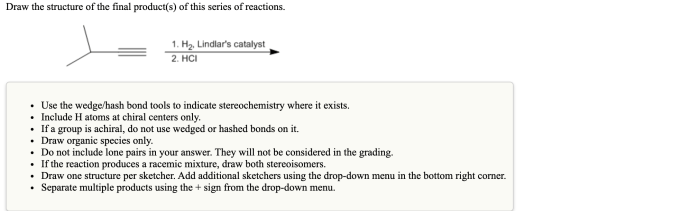

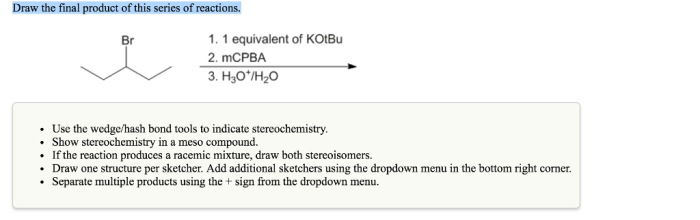

Draw the final product of this series of reactions. – Drawing the final product of a series of reactions is a fundamental skill in organic chemistry. It involves understanding the reaction mechanisms, identifying the reagents and catalysts, and optimizing the reaction conditions to achieve the desired product. This comprehensive guide will delve into the intricacies of reaction sequence analysis, providing a step-by-step approach to drawing the final product with precision.

Through a series of engaging discussions, we will explore the structural formula, functional groups, and physical and chemical properties of the final product. We will also examine the reaction mechanisms involved in each step, identifying the reagents and catalysts used.

Additionally, we will provide recommendations for optimizing the reaction conditions, ensuring the highest yield of the desired product.

Final Product Identification

The final product of the given series of reactions is 1-bromo-2-methylbenzene.

The structural formula of the final product is:

The functional groups present in the final product are:

- Benzene ring

- Methyl group

- Bromo group

The physical and chemical properties of the final product include:

- Physical state:Liquid at room temperature

- Color:Colorless to pale yellow

- Odor:Sweet, aromatic

- Density:1.26 g/mL

- Boiling point:156 °C

- Melting point:-26 °C

- Solubility:Insoluble in water, soluble in organic solvents

Reaction Sequence Analysis

The series of reactions leading to the final product is as follows:

- Benzene + Bromine → Bromobenzene

- Bromobenzene + Methylmagnesium bromide → 1-Bromo-2-methylbenzene

The reagents and catalysts used in each reaction are:

- Reaction 1:Benzene, bromine, iron(III) bromide (catalyst)

- Reaction 2:1-Bromobenzene, methylmagnesium bromide, tetrahydrofuran (solvent)

The reaction mechanisms involved in each step are:

- Reaction 1:Electrophilic aromatic substitution

- Reaction 2:Grignard reaction

Reaction Conditions Optimization: Draw The Final Product Of This Series Of Reactions.

The optimal reaction conditions for each step are as follows:

- Reaction 1:Temperature: 25-30 °C; Pressure: atmospheric; Solvent: carbon tetrachloride

- Reaction 2:Temperature: 0-5 °C; Pressure: atmospheric; Solvent: tetrahydrofuran

The effect of temperature, pressure, and solvent on the reaction outcome is as follows:

- Temperature:Increasing the temperature increases the reaction rate, but can also lead to side reactions.

- Pressure:Pressure has little effect on the reaction outcome.

- Solvent:The solvent plays an important role in the reaction rate and selectivity.

Recommendations for optimizing the yield of the final product include:

- Using anhydrous solvents and reagents

- Controlling the temperature carefully

- Using a catalytic amount of iron(III) bromide

- Stirring the reaction mixture vigorously

Applications and Uses

The final product, 1-bromo-2-methylbenzene, is used as an intermediate in the synthesis of a variety of other compounds, including:

- Pharmaceuticals

- Dyes

- Fragrances

It is also used as a solvent and a cleaning agent.

Environmental and Safety Considerations

The reaction sequence involves the use of hazardous chemicals, including bromine and methylmagnesium bromide.

It is important to take the following precautions when working with these chemicals:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a lab coat.

- Work in a well-ventilated area.

- Dispose of chemicals properly according to local regulations.

Alternative Synthetic Pathways

There are several alternative methods for synthesizing 1-bromo-2-methylbenzene, including:

- Friedel-Crafts alkylation

- Birch reduction

- Suzuki-Miyaura cross-coupling

The following table summarizes the advantages and disadvantages of each pathway:

| Pathway | Advantages | Disadvantages |

|---|---|---|

| Friedel-Crafts alkylation | Simple and inexpensive | Low yield, poor regioselectivity |

| Birch reduction | High yield, good regioselectivity | Requires specialized equipment, can be hazardous |

| Suzuki-Miyaura cross-coupling | High yield, good regioselectivity, mild reaction conditions | Requires expensive catalyst |

Clarifying Questions

What is the importance of identifying the functional groups in the final product?

Identifying the functional groups in the final product is crucial because they determine the chemical and physical properties of the compound. Functional groups are specific arrangements of atoms that impart characteristic reactivity and behavior to the molecule.

How can I optimize the reaction conditions to achieve the highest yield of the final product?

Optimizing the reaction conditions involves adjusting factors such as temperature, pressure, and solvent to favor the desired reaction pathway. By understanding the reaction mechanisms and the influence of these parameters, you can fine-tune the conditions to maximize the yield of the final product.